Levenstond Seafood was established in 2007 when founder Axel Verberkmoes had the intention of processing salmon for Delhaize with about 10 employees. In 2017, the Belgian company was capable of processing 5,000 tonnes of fish per year into 30,000 consumer packages per day, in two production departments, four cash&carries, and two sourcing platforms, one of which located in Vietnam. In total, 130 people contribute to an annual turnover of 55 million Euros. Pangasius fillet is flown in fresh from Vietnam on daily basis, also cod and other whitefish from Iceland. The ordering retailer receives the order four hours later. The family company serves almost the whole retail sector in Belgium, including Delhaize, Colruyt, Spar, Carrefour, Lidl, and Aldi.

Automation for the industry

Besides Levenstond Seafood, the group of family companies consists of Vandermaesen which was taken over in 2012 and LSF Services, which was created out of necessity. Axel: “Nowadays, as a food company, you can no longer do without IT. It has become a huge expense for companies. The work is often outsourced as the companies themselves do not have enough know-how. It is expensive and the result is often insufficient. We are talking about links, control, ERP software and so on. As a food company, you have a huge amount of obligations. You must be able to pass on information to your customers. Retailers are demanding because the market requires them to be. The customer wants to know with what boat you are fishing, whether you use hooks and when the fish is caught from the sea. What has been done to the products, what temperature they have been processed at, If you have to be able to answer all those questions, apart from quality control and margin controls, you need enter the IT domain quickly. To this end, we have established LSF Services, which focuses on domotics for the food plant.”

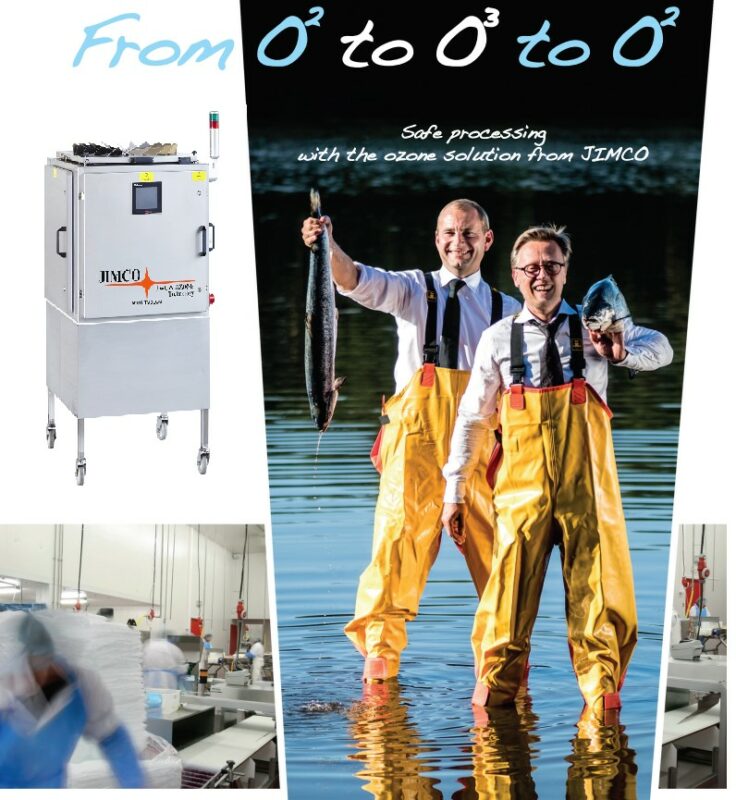

Ozone based cleaning

Axel: “When you process fish, every day again you introduce listeria to the production process. That is inherent to the product. At the start, we have set up a system to disinfect with chemicals. First cleaning, then disinfecting with a disinfectant product, such as chlorine. That works, but that only cleans the surface and machines require more. They have holes and gaps. After several years, it has emerged from testing that it is becoming more and more difficult to obtain good results. That is why we actively went in search for a better solution. We got into contact with the people from JIMCO, who presented us with a device based on ozone, which ensures that, in fact, the whole area, each hole, and even the air is sterilized. Now we have three of these devices. A fantastic investment.”

From O³ to O²

When working with ozone, the air in the room is changed into O³, treats the room and goes back to O² after the treatment. Axel: “You must ensure that at that moment, nobody can enter, the cleaning is timed and measured and also that you can report afterward. So, the device by itself, which is a standalone device, is a part of the solution. Because we have LSF Services, we started talking to Jimmy Larsen to turn the standalone solution into a complete concept, which makes the system user-friendly. The devices from JIMCO are amazing. We gain a lot of time during the cleaning process, use half of the water, do not use chemicals and thus work more environmentally friendly and cost saving. In addition, the results are available online and they are always very good. Above 7 ppm we know we have cleaned well, but we are always above it. You also note from the results that the cleaning gets better and faster. While initially, it took seven to eight hours to achieve a good result, now it is done in two to three hours.” Axel adds: “It is important to note that the process of converting to ozone, to O³, is reversible. After a few hours, we emit neutral air again.”

Proactive with FAVV

“The Belgian FAVV and the Dutch NVWA are often approached with suspicion”, Axel believes. “But when you approach them proactively and talk to them, the contact is often fine. That is what we did when we started cleaning with the Jimco FLO-D. We also brought our test results straight away. The FAVV is very positive about our company and the results. Which are simply wonderful. This investment pays back within one year.”