News

Air pollution

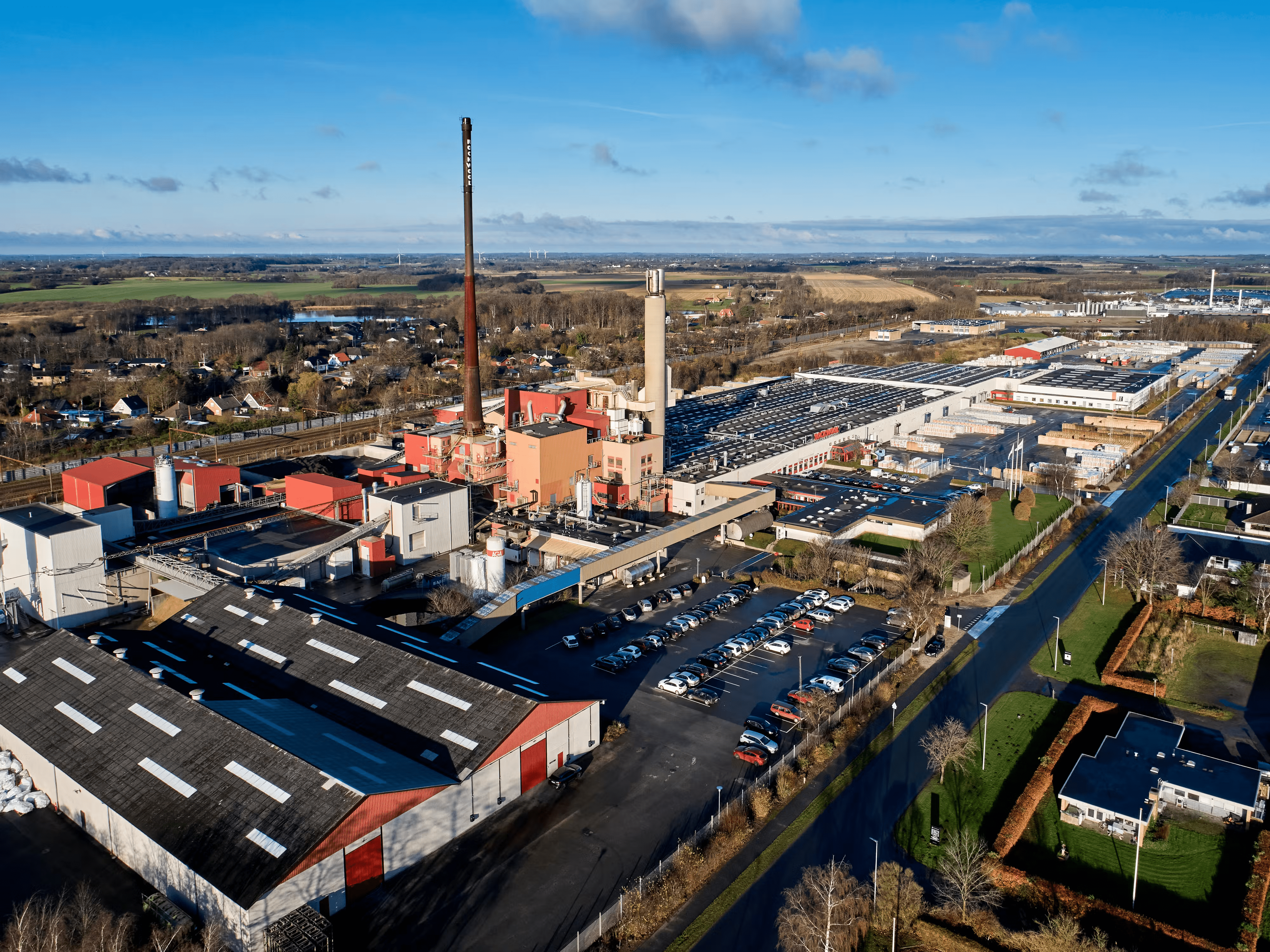

Air pollution from industry production

Weel & Sandvig awarded PEMS contract for global methane emissions monitoring from BP oil and gas operations

LONDON & COPENHAGEN – bp and Weel & Sandvig announce that bp has awarded Weel & Sandvig the global PEMS (Predictive Emission Monitoring System) contract for monitoring methane emission from bp production facilities.

bp’s ambition is to become a net zero company by 2050 or sooner and to help the world get to net zero.. To achieve this, bp has set out 10 net zero aims. Aim 4 – reducing methane is “to install methane measurement at all our existing major oil and gas processing sites by 2023, publish the data and then drive a 50% reduction in methane intensity of our operations”.

| “We believe our new strategy provides a comprehensive and coherent approach to turn our net zero ambition into action. This coming decade is critical for the world in the fight against climate change, and to drive the necessary change in global energy systems will require action from everyone.”,

Bernard Looney, BP Chief executive officer |

Gas turbines used to power oil and gas facilities are a significant source of methane emissions. bp has selected Weel & Sandvig as a key technology provider to provide emission monitoring systems for all gas turbines in scope.

“We are proud to be selected as one of the key technology suppliers supporting bp on its path towards net zero” Jan Sandvig, Managing Partner Weel & Sandvig.

PEMS is a recognised technology for accurate continuous emission monitoring with a long-standing record of monitoring other atmospheric emissions such as nitrous oxides. Weel & Sandvig has developed and provided PEMS systems since 2005 and has pioneered technical development in the field. The solution (WS.PEMS) is based on deep understanding of the fundamental combustion process to accurately determine emissions, using a combination of high accuracy turbine measurements and advanced analytics. The addition of cloud-based computing accelerates the deployment of the solution to bp’s global fleet of turbines.

[caption id="attachment_141209" align="alignnone" width="450"]

“As part of Aim 4 we want to move from methane estimates from simple emission factors to actual quantification of emission from individual equipment based on accurate and reliable monitoring technologies. We have selected PEMS as the most appropriate method for all our gas turbines” Peter Evans, bp.

The PEMS system covers bp upstream operation in 35+ facilities across the world providing real time methane emission data for more than 150 emission sources.

You should consider reading

News

Energy efficiency in industry

+4

Denmark's industrial sector cuts emissions by 17%

29 April 2024publications

Resource efficient production

+15