News

Recycling of waste to material

Resource efficient production

New technique eliminates and destroys pollution with gas burner

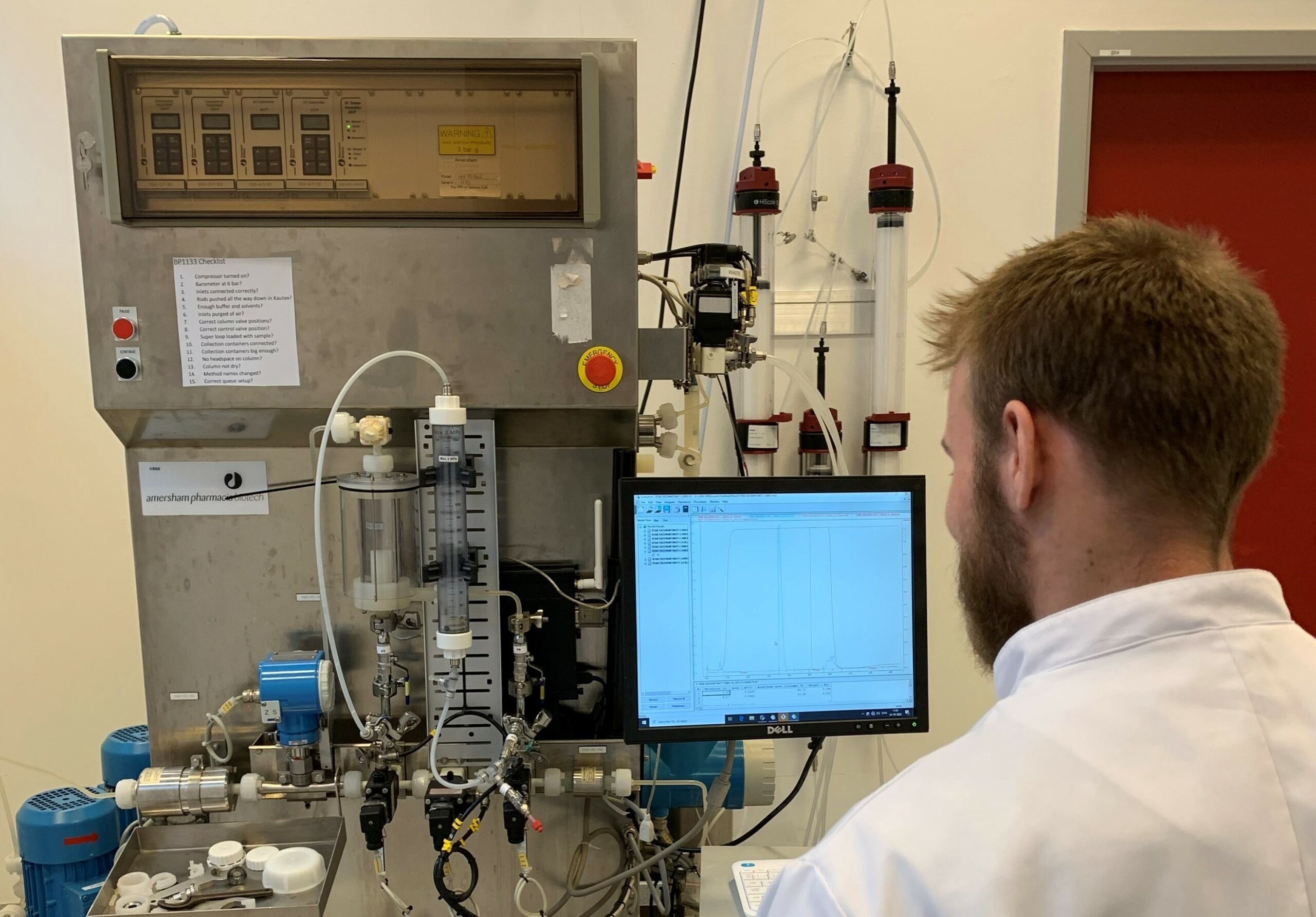

The new method is the result of a development project that tested whether gas burners could be used to heat soil in combination with destroying chlorinated toxic solvents. The project started in mid-March 2013 and was completed at the end of 2013. The Capital Region in Denmark initiated the project, with Orbicon acting as consultant. In addition, Arkil A/S, TPStech S.A. and Force Technology were partners on the project.

Arkil and Orbicon had previously worked on similar projects together. Project manager Kim Jensen from Arkil refers to a project which produced extremely good results, where they suppressed the pollution caused by heat.

- We have worked with Orbicon in a number of projects in different roles, and we have generally had a very good professional relationship, said Kim Jensen.

- The exciting thing about this project is that we had never tested this new purification technique in Denmark before, so it was interesting to see how the process went. The method is also ideal for hydrocarbon pollution where TPStech has made several successful purifications, he concludes.

Toxic waste destroyed on site

The soil was heated with gas burners, while at the same time the flame eliminated the chlorinated compounds absorbed in the air. This was the first time this technique had been applied. Based on the successful results of this method, it is expected that a lot can be saved on future projects, as the method reduces the need to treat the absorbed vapour. The results show that the vapors were destroyed almost 100% by the gas flame. Other toxic waste products produced during the experiment were not measured.

Development leader Thomas H. Larsen from Orbicon explains that the beauty of this method is that it can effectively collect and destroy chlorinated solvents in one single process.

- First the ground is heated with gas burners, so that the contaminated chlorinated solvents evaporate. Then the evaporated solvents head to the gas burners where they are combusted and converted to hydrochloric acid and carbon dioxide. The hydrochloric acid is contained in the discharge from the combustion. FORCE Technology as part of the study evaluated that the corrosion in the burners is not a significant problem, which one might have expected it to be, Thomas Larsen said.

- When there is the successful destruction of the chlorinated solvents in this way, the need to treat the gas further is significantly reduced, compared with other purification techniques tested by heating. In addition, the materials and energy used in this process are much less, Thomas Larsen stresses.

You should consider reading

News

Energy efficiency in industry

+4

Denmark's industrial sector cuts emissions by 17%

29 April 2024publications

Resource efficient production

+15