Industrial Symbiosis: a model for growth in the circular economy

Through industrial symbiosis, 25 Danish companies are exchanging surplus materials and creating green business models.

Read the full casePerspective

Circular business models

Circular value chains

Resource efficient production

Through industrial symbiosis, 25 Danish companies are exchanging surplus materials and creating green business models.

Read the full caseIndustrial symbiosis is a method for using scarce materials effectively and sustainably, representing a way for companies to lower environmental impact and production expenses.

Through the “Sustainable Synergies” project facilitated by Port of Aalborg, Aalborg University and energy cluster House of Energy, 25 Danish companies have exchanged residual and surplus products such as water, energy, or materials.

The project was designed to improve the competitiveness of SMEs in Aalborg East by developing green business models that would improve energy efficiency and resource efficiency through a facilitated industrial symbiosis.

The companies involved in the symbiosis have experienced a range of benefits. For example, an exchange of surplus resources has resulted in direct benefits, such as reduced waste management and materials procurement costs. Additionally, extra income was generated through product innovation and new products, as well as creating new markets and/or customer groups.

Additionally, several positive environmental results have been achieved:

Read more: Industrial symbiosis: A model for growth in the circular economy

The Danish deposit and return system for recycling drink cans and bottles are a prime example of a circular system creating several circular economy benefits for society.

Read the full caseIn 2021, Denmark reached a 93% return percentage of disposable packaging, recycling 1.9 billion cans and bottles for reuse.

This was largely due to Dansk Retursystem: The Danish deposit and return system for recycling drink cans and bottles. A common circular return system, making it possible to turn in your used beverage containers in supermarkets and kiosks across Denmark while receiving a deposit in return as cash.

The deposit and return system creates several circular economy benefits:

The Danish deposit system can be seen as an inspiration source to increase recycling rates and support the circular economy, especially in order to reach the EU goal of 90 % collection goal of plastic bottles by 2029.

Read more: The Danish deposit & return system for recycling drink cans and bottles

Through minimizing its carbon footprint, The Circular House har been named a blueprint for circular construction.

Read the full caseWith the building industry responsible for a sizeable amount of global CO2 emissions (approximately 39% in total), the need for a circular approach to construction and design is required. One way to do so is to recycle or reuse building materials, thereby maximising their lifespan and reusability.

A prime example of this is The Circle House, which is expected to be completed north of the Danish city of Aarhus in 2023. The Circle house project, led by 3XN Architects, is devised to be a blueprint for circular construction in Denmark, with 90% of its building material able to be demounted and reused or resold without loss of value.

Additionally, besides using concrete and cement as the main building material, the building project is set to minimize its CO2 footprint by using alternative materials, such as:

Once completed, the Circular House will be the world’s first social housing project constructed according to circular principles. The hope is that the Circle House will create valuable learnings on how circular buildings function in daily life, as well as provide a way of reducing carbon footprint within the construction sector. It is estimated that a circular approach to buildings will reduce CO2 emissions from materials used in the built environment by 38% by 2050. Furthermore, it is estimated that Denmark has the economic potential in implementing a circular economy in its building industry amounting to approximately € 7.75 billion per annum up to 2035.

Read more: Denmark’s first circular social housing project

As the first in the world, Re-Match uses patented state-of-the-art technology to separate worn-out artificial turf into raw, clean components, which can then be re-used or recycled in the turf industry or in other industries. Re-Match is able to separate every part of the worn-out synthetic turf into rubber granules, sand and plastic fibres. The technology is so effective that almost 100% of the components can be either reused or recycled. Re-Match has now succeeded to include its recycled products into high-quality turf yarns, acoustic panels, etc. by using innovative technologies.

Every artificial turf pitch that is recycled by Re-Match results in a saving of 400 tonnes of CO2, when compared to incineration, which is equivalent to 1.4 million plastic bags, or 250 tonnes of waste. Conversely, the process used to separate artificial turf emits less than 20 tonne of CO2 per pitch.

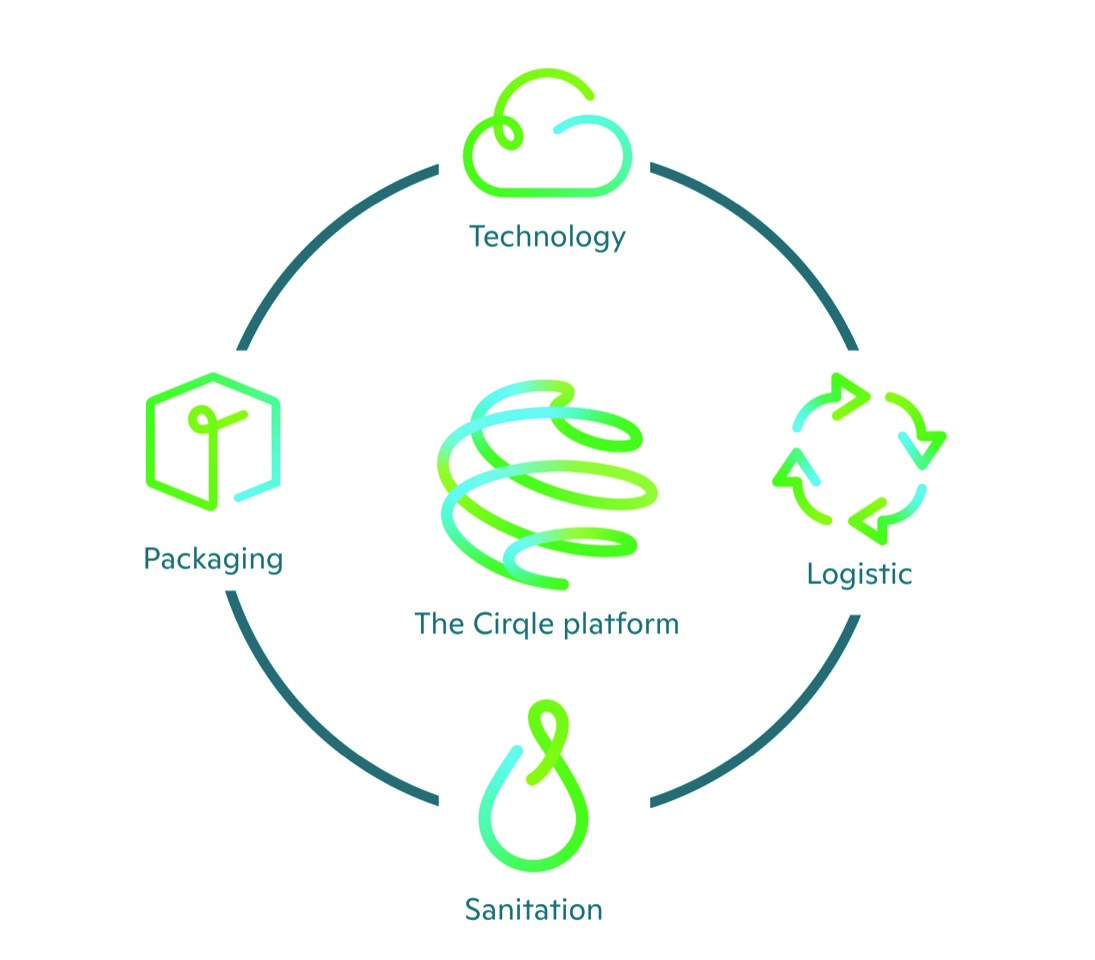

Today’s requirements for sustainability in packaging are increasing at every step of the value chain and consumers are increasingly looking for new ways to reduce packaging usage and waste. One way to do so is to offer circular models of reuse for food packaging.

One of Europe’s leaders in designing and producing circular packaging solutions in the food industry, Plus Pack has partnered up with Circqle, a start-up company delivering packaging as-a-service, to develop a circular reuse model for the packaging of foods.

The partnership is focusing on developing a unique system and digital solutions to handle packaging in a closed-loop, focusing on four areas of reuse packaging-as-a-service:

The reuse packaging-as-service offers a new circular consumption model, which reduces packaging and waste, thus encompassing the potential to reduce CO2 emissions by up to 60% when compared to single-use packaging.

Read more: Closed loop in reuse packaging-as-service

A Danish partnership offers circular models of reuse for food packaging.

Read the full caseThe turbines of the wind industry’s early days are reaching their end of life. Some are life extended while others will be decommissioned during the next years. To combat this problem, the DecomBlades innovation project has commited to try to find a sustainable way to dispose the wind turbines with respect to the environment, health and safety of workers. Today, significant progress has been made as the project has succeeded in extracting and processing high-quality glass fibres, the principal wind blade component, from retired 37-meter tall wind turbines.

The DecomBlades project is funded by Innovation Fund Denmark with MAKEEN Energy having developed the large-scale pyrolysis test plant. Following the successful quality approval of glass fibres obtained from decommissioned wind turbine blades, the material was subjected to remelting at 3B’s facility in Norway this past September. In a collaborative effort alongside DTU Wind and Energy Systems, both 3B and DTU will now examine and verify the properties of the generated glass fibres with remelted content.

Read more: Project achieves breakthrough in recycling wind turbine blades

The driving force behind the founding of the company “Gamle Mursten” (“Old Bricks”) was the desire to prevent resources of natural bricks from being wasted. Since its founding, “Gamle Mursten” has expanded greatly, and is now a large-scale cleantech production company with patented cleaning technology which ensures that building waste can be reused without the use of any chemicals.

The old bricks are collected, cleaned with vibration technology, manually checked one by one and finally stacked by robots before being shipped to new sites. Saving more than 95% of the energy otherwise used to manufacture new bricks, this method of re-using old bricks is an example of perfect circular economy passing the resources of one generation on to a new one. By applying its method to two thousand bricks, “Gamle Mursten” also prevents the emission of one tonne of CO2. Realdania Byg and 3XN Architects used 300,000 old bricks making the Castle of Hindsgavl hotel (see picture), saving the environment of 150 tons CO2. (Courtesy: Realdania Byg and 3XN Architects)

With over 30% of Denmark’s waste coming from construction, upcycling of used building materials has become an area of increased focus. As a result, traditional disposal methods that send waste insulation to landfill sites and crush porcelain and sanitaryware to make road fill are being replaced by a new, greener alternative jointly developed by three Danish companies.

Construction waste from Danish recycling centres is delivered to RGS90, a company which specialises in the processing, sorting, removing and recycling of waste products. Here, all unwanted materials are removed. Recyclable ROCKWOOL insulation and ROCKFON acoustic panels are then separated from the unrecyclable insulation before being granulated. Porcelain and sanitaryware are crushed before being sent to the ROCKWOOL production facility, where they are used to manufacture new, recyclable insulation.

(Courtesy: RGS90, ROCKWOOL and Combineering A/S)

The Swan childcare centre is constructed according to circular principles by reusing old materials.

Read the full caseWith the construction industry responsible for approximately half of all resource extraction on a global scale, the need to transform the building to one that operates according to circular economy principles is imperative.

A prime example on a possible approach can be found in Gladsaxe Denmark, where the architecture firm Lendager has been in charge of building “the Swan” childcare. Taking its name from its resembling of a flying swan, the childcare has been built on the site of an old school reusing materials such as bricks, roofing tiles, wood rafters, steel bike racks, concrete, lamps, and even the school’s old clock. All of which drastically reduces the building’s amount of waste and its CO2 footprint.

The Swan childcare centre is the first building being constructed according to circular principles to be awarded the Nordic Swan EcoLabel, awarded to buildings reducing its environmental impact and advancing circular economy. The certification is given to buildings adhering to criteria including:

The combined demolition and construction project has created valuable new knowledge, insights, and experience regarding how to design and construct in a circular manner.

Read more: A Swan takes shape

Danish Crown, one of the world’s biggest pork producers, is cooperatively owned by Danish farmers who are both our suppliers and owners. Production and possibilities for optimising side streams is seen across the value chain from farm level to slaughterhouse. The value chain is no stronger than its weakest link, the result being today that Danish Crown represents one of the most efficient meat producers in the world. The secret behind Danish Crown is the focus not only on producing meat, but also on producing and recycling other products such as sustainable energy, fuels, feed, nutrients and inputs for the pharmaceutical industry.

Resource efficiency is a key part of the DNA. Investments in the value chain, such as breeding of animals, new effective stables, feed optimisation, recycling of nutrients, as well as improving energy and water efficiency, logistics and utilisation of side-streams, are interconnected. They generate valuable knowledge-sharing through the value chain, ultimately benefiting the owners. Based on this philosophy, Danish Crown demonstrates that they produce more with less, creating more value for the customers, suppliers, owners as well as society in general, the climate and environment. Circular economy principles are therefore nothing new to Danish Crown. (Courtesy: Danish Crown)

solutions

Combined heat and power production

+6

solutions

Energy efficiency in buildings

+2

publications

Energy efficiency in industry

+7