While using artificial turf for sports pitches offers several benefits when compared to natural grass, disposing of it when it becomes worn out can create significant environmental issues. However, artificial turf pitches can now become fully circular products thanks to a process that separates the turf back into the original raw materials, which can then be used instead of virgin materials in new production cycles or to make new pitches.

Using artificial turf is a popular option for indoor and outdoor sports pitches, stadiums, arenas etc, as it offers a range of benefits when compared to natural grass. Firstly, artificial turf does not wear out from intensive use in the same way that natural grass pitches do. Secondly, artificial turf can be used in all sorts of weather and climates, which allows more sports matches and training sessions to be conducted. Thirdly, nor does artificial turf require sunlight, making it an appropriate solution for both indoor and outdoor sports pitches, as well as a less costly one, given that natural grass pitches subject to a lack of sun need to employ expensive methods such as infrared lighting to assist the grass in growing. Finally, from a resource consumption perspective, artificial turf pitches do not require water or fertilisers.

All these aspects make it easier to participate in sports and recreational activities more frequently, for longer periods of time and in spaces not normally considered suitable, meaning the use of artificial turf accrues significant public health benefits.

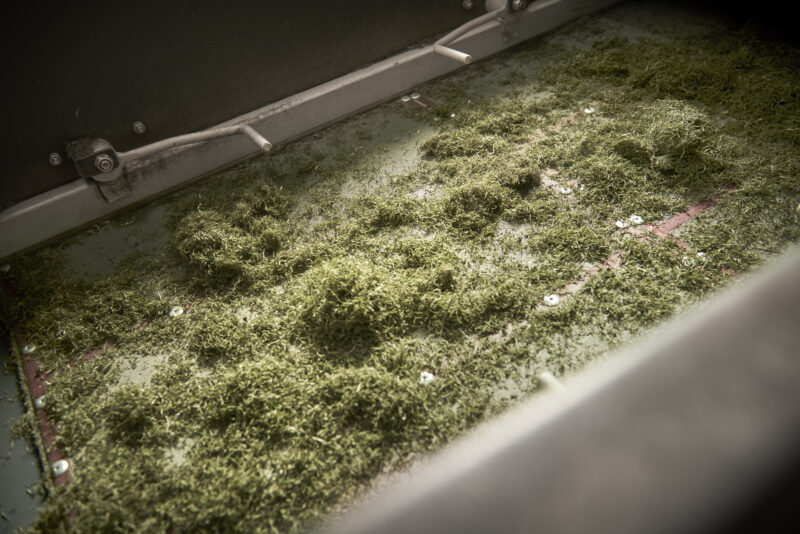

However, the challenge is what to with the artificial turf when it needs to be replaced (normally after 8-12 years). Sending the worn-out turf to landfill or incinerating are typical, but not ideal, solutions. This is because incinerating the turf results in 400 tonnes of CO2 being emitted 1 and sending the turf to landfill bears the risk of chemical waste and microplastics entering the groundwater, as well as subjecting the owner to expensive disposal fees. Moving the turf to a new location and installing it only delays the problem.

In 2020 alone, 14,000 worn-out artificial turf pitches were either incinerated or sent to landfill. The plastic components of these pitches alone are equivalent to 19.5 billion plastic bags. Furthermore, it is estimated that 52,000 pitches will need to be replaced in 2030. These numbers highlight the need to find a viable solution to the challenge of making the use of artificial turf more sustainable and a truly circular product.