Historically, the not-for-profit housing sector in Denmark has incorporated societal and social responsibility into the design of its dwellings. Now, the sector is seeking to revolutionise social housing in the country by creating projects constructed according to circular principles.

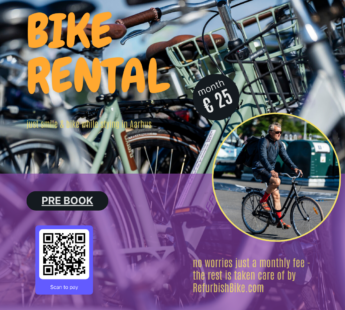

To this end, the Circle House project was established in 2017. Consisting of 60 social housing units, Circle House is located in the Lisbjerg Hill district – a development zone focused on sustainability in the north of Aarhus, Denmark’s second largest city. With a mixture of two and three storey terrace houses and five storey apartment blocks, the project will have a building density of between 65 – 80 per cent. Construction is expected to be completed by mid 2023.

Consisting of over 60 partners gathered from across the entire building value chain in Denmark, and open to anyone who wishes to participate, the project aims to develop and disseminate knowledge about circular construction across the industry and across silos. Circle House is devised as a lighthouse project that can function as a blueprint for the entire construction industry in Denmark, as well as decision makers, on how it to build according to circular principles in a manner that is not only feasible, but also sustainable and profitable. This means that Circle House is being tendered on market terms, with assistance from the Danish Environmental Protection Agency’s Environmental Technology Development and Demonstration Program (MUDP) and Realdania’s Innovation Program in Construction.

Circular construction is a relatively uncharted area and will require legislative amendments and new actors in the construction value chain to flourish. For the Circle House project, this means the development of circular tender documents, defining circular construction criteria, and new building standards. Currently, there exists an insufficient market for to purchasing used building materials, including valuing and labelling them in accordance with current Danish legislation. It is also difficult to estimate the potential for selling used building materials in 50 years.

The project’s concrete objective is that 90 per cent of the project’s materials can be demounted and reused or resold without loss of value – so-called ‘design for disassembly’. To achieve this aim, the buildings have been designed to allow for them to be dismantled and the structural components can be reused with minimal loss of value.

A key aspect of the project has been understanding how to design in a circular manner using concrete, given that valuable knowledge already exists on how to create circular buildings constructed of timber. Therefore, the ambition is that the buildings will consist of a minimal amount of different, demountable elements, where there are six in total: two different wall elements, two different beam lengths and two deck lengths. Furthermore, while cement is the material of choice, its use is minimised as much as possible in order to lessen the project’s CO2 footprint. For example, the demonstrator and mock-up of the building system shows a façade of the buildings constructed from cork and old newspapers, while eelgrass and granules have been used to provide the building’s insulation. The flooring’s underlay is made of used car tyres. Furthermore, lightweight facades have been used that can be demounted and reused again.

Architecturally, the building will be different in the sense that the buildings’ interiors, including structures, connections, and installations, will be visible on the exterior. By making the interiors part of the building’s aesthetic features, residents or the housing association will easily be able to change the size of the dwellings without having to demolish the building.

A prototype of Circular House is on display at the project’s property developer, Lejerbo’s offices in Valby, Copenhagen. All of the building’s layers, materials and products are exposed, displayed and described, and the space is currently used as an inspirational meeting and event space.