News

Power-to-x

Air pollution from industry production

Energy efficiency in industry

+2

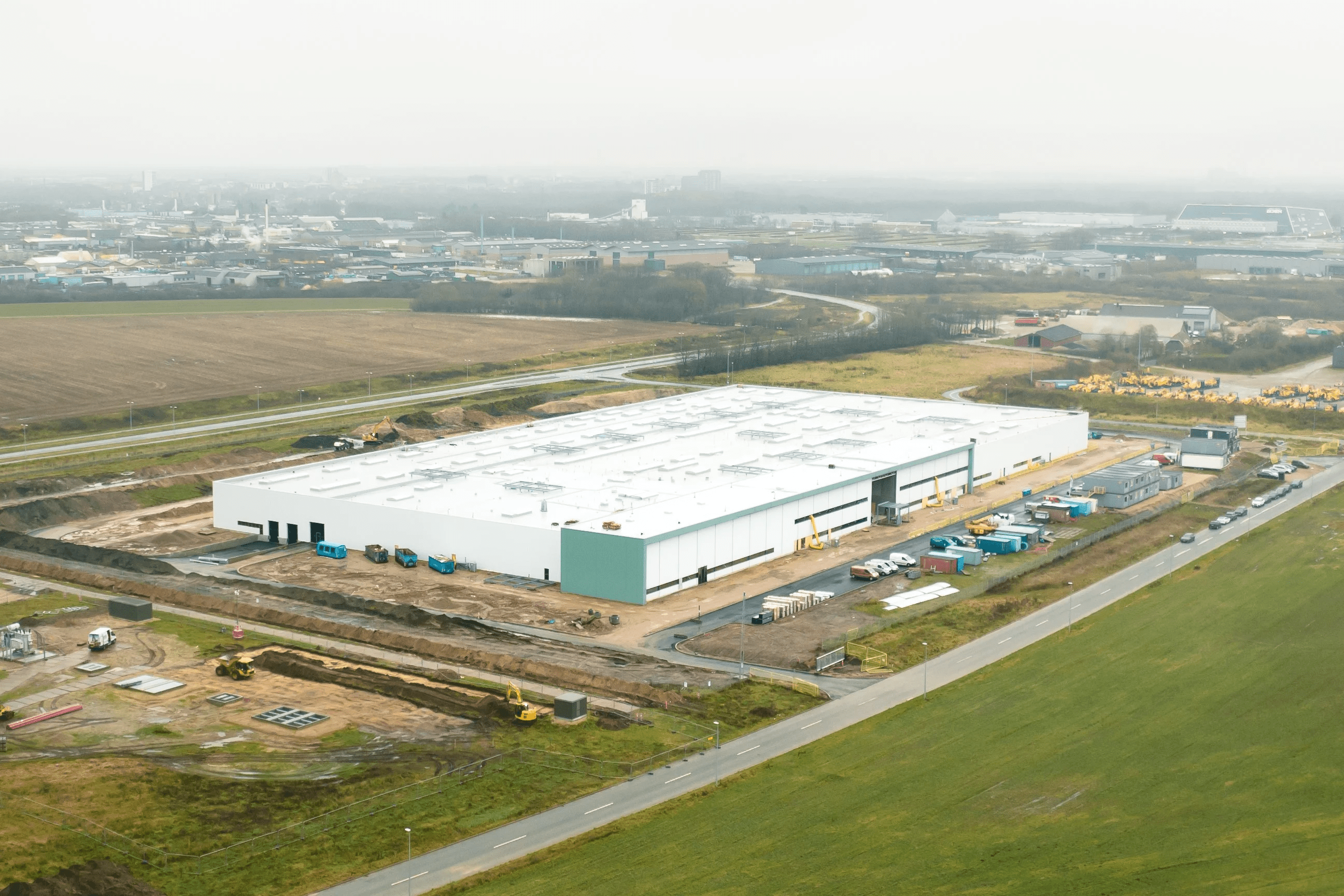

Topsoe’s electrolyzer manufacturing facility receives environmental permit

Topsoe, a global leader in carbon emission reduction technologies, has reached a key milestone in the form of an environmental permit from the Danish Environmental Agency.

The approval from the Danish Environmental Agency means, that Topsoe’s factory lives up to both Danish and EU environmental regulations and standards. This includes using the best available technical solutions, introduction of emission cleaning systems, proper waste management plans, high efficiency in use of power and water, and more. The environmental approval further allows the factory to enter into the commissioning stage and powering up equipment.

“We are very satisfied with this stamp of approval from the Danish Environmental Agency. The factory, which will produce SOEC electrolysis units will mean a solid contribution to the green hydrogen economy, and this permit confirms that we’re on track building a factory adhering to all appropriate regulatory and sustainability standards.” Kim Hedegaard, CEO Power-to-X at Topsoe

Related news: Topesoe celebrates milestone in construction of world’s first industrial scale SOEC electrolyser facility

About SOEC

Topsoe’s SOEC electrolysis technology is a modular design that operates at significantly higher temperatures compared to other electrolyzer technologies – a tested and proven process that enables industrial-scale production of green hydrogen using renewable electricity.

When coupled with waste heat from downstream production (from processes producing ammonia, methanol, or steel production), Topsoe’s SOEC technology will produces 30% more hydrogen per total power input when compared to conventional electrolyzer technologies. It further allows for the lowest levelized hydrogen cost per megawatt volume, no matter the industry.

Discover the case: World-leading electrolyser manufacturing facility