News

Wind energy

Wind farm planning and development

Wind research and development

+1

DTU tackles leading edge erosion of wind turbine blade

The Erosion project: How to avoid erosion

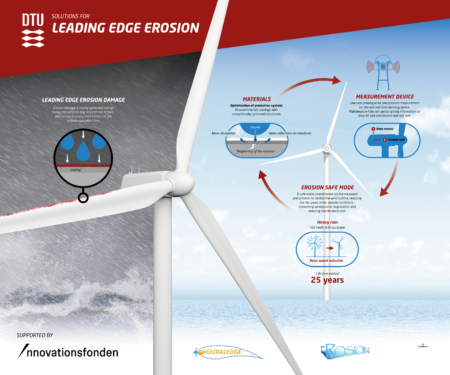

In the Erosion project researchers from DTU Wind Energy are cooperating with the industry to investigate the effect of rain and wind on wind turbine blades. The goal is, among others, to be able to develop an erosion safe mode operation for when it will be worthwhile to reduce the speed of the wind turbines, because the lower speed reduces the erosion of the blades.

"In weathers like rain and hail the savings in slowing down the speed of the wind turbines are 3%, and these are huge sums when we talk about wind farms. During a year, one day at a lower speed can extend the life of a wind turbine between 3 to 25 years”, says Charlotte Bay Hasager DTU Wind Energy.

The Duraledge project works to protect blades

While the Erosion project focuses on developing intelligent control strategies for wind turbines, the project Duraledge's focal point is developing more durable wind turbine coating materials. In cooperation with a consortium of leading wind turbine blade manufacturers and material manufacturers, Leon Mishnaevsky and colleagues from DTU are working to understand the mechanisms of degradation of wind turbine blades and to extend their lives by developing durable coatings for the blades.

“Using numerical simulation of degradation of materials at microscale level, supported by advanced microscopy analysis of the materials, one can get the full understanding of the erosion mechanisms”, says Leon Mishnaevsky. “This will lead to the computational design of new protective coatings, preventing the blade surface degradation even at high rotation speed”.

Leon Mishnaevsky and Charlotte Bay Hasager agree that the results from both projects represent the two complementary strategies for solving the problem of leading edge erosion. “In order to prevent the leading edge erosion, a combination of intelligent control strategies and better materials is required. DTU Wind Energy is working on new solutions of wind turbine blade protection, integrating these strategies”, Charlotte Bay Hasager and Leon Mishnaevsky state.

[caption id="attachment_121013" align="alignnone" width="581"]

Industry and international interest in erosion

The importance of solving the issue of leading edge erosion is reflected in the consortium partners of the two projects. They include major turbine and blade manufactures Vestas, Siemens-Gamesa and LM Wind Power as well as wind farm developers Vattenfall and RWE Renewables in addition to DMI, R&D, LM Wind Power, Hempel and Covestro.

The industrial and international interest in the topic is reflected in the attendance to the annual International Symposium organised by Mishnaevsky and Hasager. The next symposium takes place online February 2-4, 2021. For more information visit here: