Investments create momentum for green steel

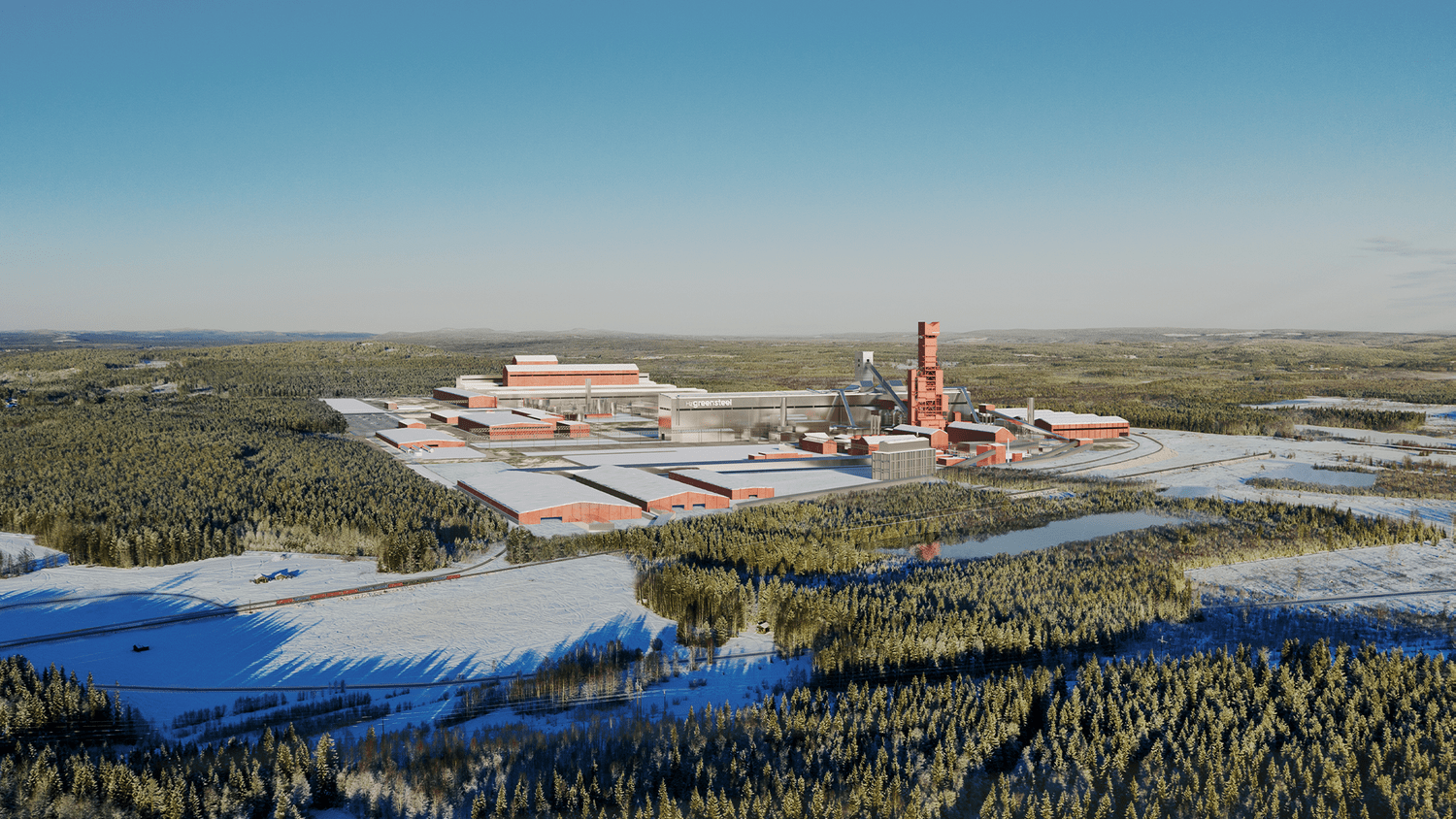

The green steel momentum is also eyed by the financial sectors as a row of Danish asset managers, including PKA and Pensam via AIP Management, announced a EUR 300 million investment in the construction of the world’s first large-scale green steel mill. Placed in northern Sweden, the ambition of the integrated plant is to deliver steel with up to 95% less CO2 emissions than conventional steel produced in a traditional blast furnace. This is achieved by replacing coal with green hydrogen in the processes where iron ore is heated and reduced so that it can later be made into steel. The green hydrogen is produced on-site in what will be Europe’s largest electrolysis plant, and the downstream finishing is electrified using electricity from renewable energy sources.

The steel mill, H2GS, is expected to produce up to 2.5 million tonnes of finished flat steel per year, ready to build everything from cars to furniture and white goods. The project, reflecting an increasing appetite from private companies, already has several agreements in place with well-known off-takers, such as Mercedes Benz, Ikea and Electrolux.

The Steel Zero Initiative

The current focus on the decarbonisation of steel reflects the global call made by the Steel Zero initiative. Launched in 2020, the initiative requires its members to make a public commitment to procure 100% net zero steel by 2050 including an interim commitment to procure, specify or stock 50% of their steel requirement by 2030. Among members sending a multi-stakeholder demand signal to shift global markets and policies towards responsible production and sourcing of steel, the shipping giant Maersk and the renewable energy leaders Ørsted and Siemens Gamesa are partnering the push to deliver a global steel transition and move away from coal-powered furnaces.