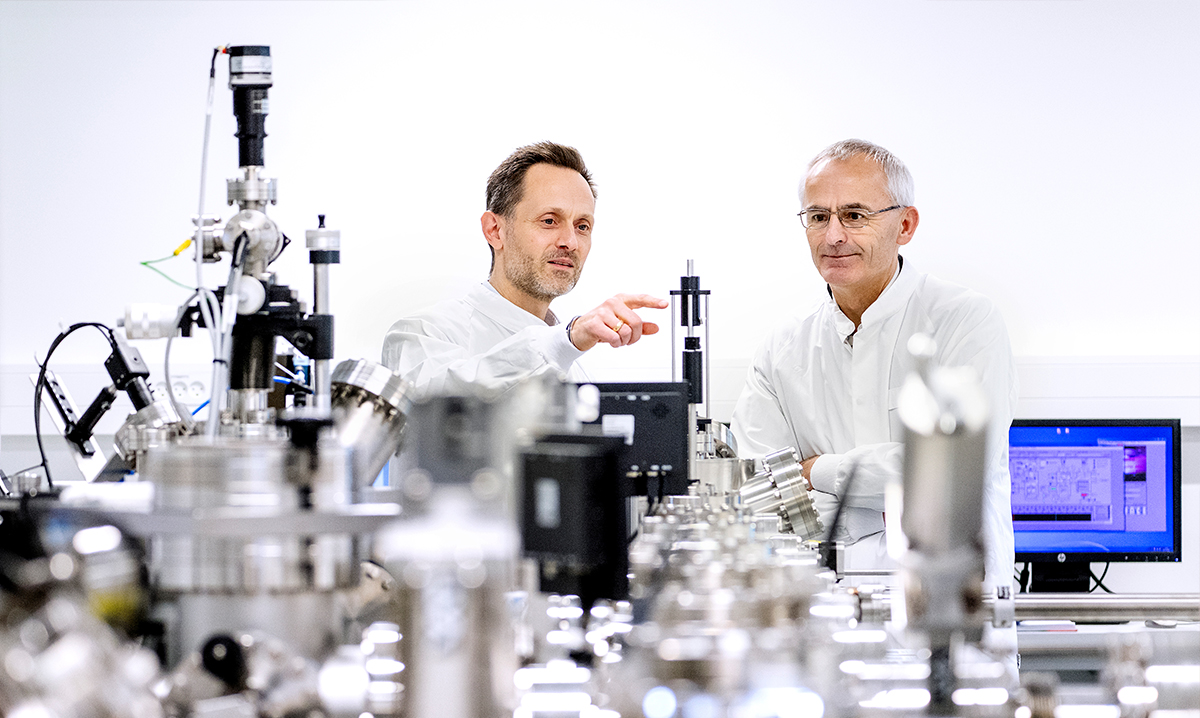

Online access to data and laboratories

CAPeX brings together leading experts and competencies from Danish universities and three international consortia for the development of a new powerful materials acceleration platform (MAP) for the rapid development of materials. A MAP combines computer simulations, experiments, and synthesis robots in a closed loop, including using artificial intelligence. The platform is expected to increase the pace of development of new materials five to ten times.

The centre is run in a partnership between the Technical University of Denmark (DTU) and Aalborg University (AAU) and is located in a new interdisciplinary ‘Climate Challenge Laboratory’ at DTU. Here, researchers from DTU, AAU, the University of Copenhagen, Aarhus University, and the University of Southern Denmark will create a ground-breaking interdisciplinary environment for Power-to-X technology in collaboration with international partners from Stanford University, Utrecht University, and the University of Toronto.

“The climate crisis is an urgent global challenge that requires a radically new approach to the development of materials if we’re to have new green technologies ready in time. The task exceeds what the individual researcher, the individual laboratory, or the individual country can solve. Therefore, we want to create a concept and a platform for a completely new interdisciplinary way of working together nationally and internationally. We do this through a number of activities, including by creating online access to data, computers, and equipment in different laboratories, so that we can share and use data from all parts of the development process as efficiently as possible,” Tejs Vegge, Professor at DTU and Head of CAPeX.

Digital twins

Professor Frede Blaabjerg from Aalborg University is co-lead in CAPeX and heads the development of a so-called digital twin, where researchers in a virtual universe can design, test, and analyse new materials, cells, and systems before they are manufactured. The objective is to make it possible to predict how materials and systems change their properties and behaviour from the atomic level right up to the optimisation of an energy island.

“The digital twin is a virtual simulation of the processes and materials that are to be tested and developed in CAPeX. As the twin is based on mathematical simulation, we’re not slowed down by the normal time and resource consumption for setting up tests. On this basis, we can both describe processes that, in reality, require a long time, and test materials with many different qualities at once,” Frede Blaabjerg, Professor and co-lead in CAPeX.

Green fuels

One of the first tasks in CAPeX will be to develop new materials for the production of liquid green fuels, so that the technology becomes much more efficient and sustainable than today, and can be spread globally. This is followed by the construction of a comprehensive education programme for the next generation of researchers and Power-to-X experts, who will have access to more than 100 PhD and postdoctoral positions during the life of the centre, including through three fellowship programmes with exchange stays at Stanford University, University of Toronto, and Utrecht University.

Over the 13-year project period, CAPeX will expand the platform for research into the composition of new materials and new Power-to-X technologies that use green power from wind turbines to produce sustainable chemicals, plastics, medicines, and even proteins for foods.

Source: DTU