Solution provider

Case

Wastewater management

Water management

Add the case to your visit request and let us know that you are interested in visiting Denmark

Operators at the Downers Grove (Illinois) Wastewater Treatment Center worked for four years with the vendor to repair the compressor on the gas recirculating mixing system in Primary Digester No. 1. The compressor ran, but it wouldn’t move any gas.

The plant’s general manager took a tour of self-sufficient Danish wastewater treatment plants and their equipment vendors. At the Landia factory in Denmark, he saw the externally mounted GasMix digester mixing system.

Compared to other technologies, the GasMix retrofit was more economical to purchase and install. In March 2017, Downers Grove became the first municipality in North America to operate a GasMix system. The plant provides primary settling followed by secondary treatment and ammonia removal using activated sludge, tertiary sand filtration and seasonal disinfection. The facility has three primary digesters and two secondary digesters. Digester gas is stored, treated and used in the combined heat and power facility.

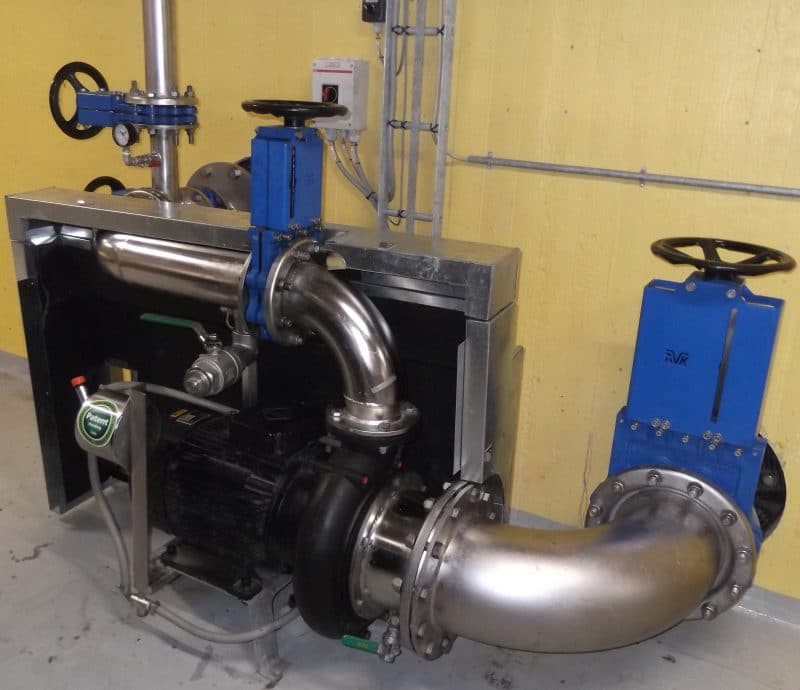

Landia Inc. helped Downers Grove size the equipment for Digester No. 1, a 55-foot-diameter concrete cylinder with a cone bottom, a floating cover and a liquid volume of 460,000 gallons.

Compared to other types of digester solutions the Landia GasMix can easily be retrofitted, has a small foot print and is in a class of its own with regards to ease of service and maintenance. When it comes to Health & Safety, the Landia GasMix has completely eliminated the need of opening the digester for any kind of service. In other words no risk of biogas leaking from the digester, no need for the use of breathing apparatus etc.

The solution provided resulted in a 20% increase in biogas production and 10% increase in solids reduction, which in the end has the positive affect, that less sludge is produced. This means: reduced environmental foot print due to more biogas and less transport of sludge.