Solution provider

Case

Energy efficiency in industry

Add the case to your visit request and let us know that you are interested in visiting Denmark

Concentrated solar power, or CSP, is one of the two main technologies to produce electricity from the sun’s energy. Until recently, CSP has been used to produce electricity only when the sun was up. This has been a problem, since the production does not fully match the typical demand curve for electricity. A solution to the problem is to add a thermal storage system based on molten salt, which allows the plant to generate electricity even when the sky is overcast and after the sun goes down without using a backup system powered by fossil fuels. This means the plant can operate for 18 hours straight instead of 12 hours – an increase of six hours or 50 percent. At the heart of the thermal storage system is an Alfa Laval Packinox heat exchanger specifically developed for this application.

Thanks to recent acquisitions, Alfa Laval can also supply other vital equipment to CSP plants, including a variety of heat exchangers, condensers and dry coolers.

See how a CSP plant with thermal storage operates by reading the whole story by following the link to our website.

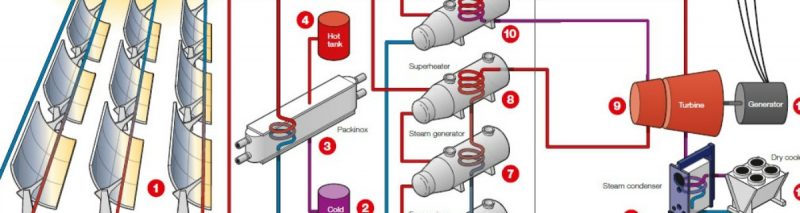

This is how a CSP plant with thermal storage operates

When the sun shines, the solar concentrator field (1) heats up a circulating loop of thermal oil. Some of the heated oil is sent directly to the steam generator at the power island for immediate production of electricity. Excess heat is sent in parallel to thermal storage for later use. During the storage mode, salt is pumped out of the cold storage tank (2), heated by the hot oil in an Alfa Laval Packinox heat exchanger (3), and then stored in the hot salt tank (4). On cloudy days and after sunset, the fluid circulation is reversed: Salt is pumped out of the hot tank, cooled in the oil-tosalt Packinox heat exchanger, then stored in the cold tank. The heat energy contained in the hot salt tank is thereby transferred to the hot oil circuit, which in turn allows the generation of steam and the production of electricity. I n the steam process, water is heated into pressurized steam using a four-step process: First the feedwater heaters (5), then the economizer (6) and the steam generator (7), and finally the superheater (8). After going through, the first stage of the turbine (9), the steam is reheated in the reheater (10) before powering the second stage of the turbine, which in turn drives the generator (11) that produces electricity. The transformer feeds the electricity into the transmission grid (12). Steam that comes out of the turbine is condensed back into water. Since many CSP plants will be located in desert environments, Alfa Laval offers a solution that minimizes the use of water in this process. It combines an Alfa Laval AlfaCond steam condenser (13) and an Alfa Laval dry cooler (14), which uses air instead of water as cooling medium, to handle the vacuum condensing requirement. The only water used circulates in a closed loop running back and forth between the AlfaCond and the dry cooler.