Solution provider

Babcock & Wilcox Renewable has supplied more than 650 waste-to-energy plants (WTE) worldwide.

Case

CHP

District energy

District heating

+2

Babcock & Wilcox Renewable has supplied more than 650 waste-to-energy plants (WTE) worldwide.

Add the case to your visit request and let us know that you are interested in visiting Denmark

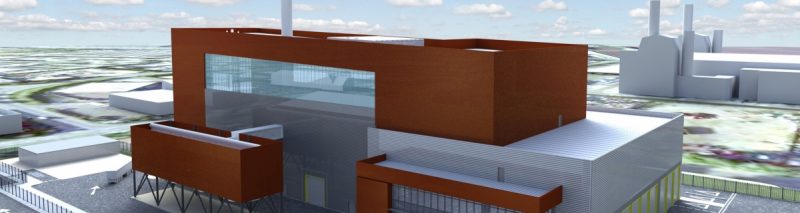

B&W Vølund, working with UK construction partner, Interserve Construction Ltd., was awarded the EPC/turnkey contract for the plant in Peterborough. The facility is provided by Viridor under a 30-year contract signed with Peterborough City Council. The plant was handed over to Viridor in December 2015, on time and within budget.

The plant processes 85,000-tonnes of residual household, commercial and industrial waste from the local area. It generates 7.25 MW of green energy, corresponding to the electrical consumption of 15.000 households.

Before the construction of the plant, 94 % of Peterborough’s waste was not recycled and left as landfill. The landfill will instead be combusted in the process of producing electricity and with guaranteed low emission levels; the power plant is contributing to Peterborough Council’s Blue Sky project to provide sustainable energy in a smart city environment.

In the fall of 2014, UK’s first ever DynaGrate® was installed in the Peterborough facility. DynaGrate® is Babcock & Wilcox Vølund’s state-of-the-art combustion grate which is one of the most advanced combustion grates on the waste-to-energy market today.

Peterborough City Council’s Director of Resources, John Harrison also recommends the small, yet highly efficient, energy recovery facility solution to other city councils.

He said: ”This plant will produce in excess of 7 MW of electricity. That is a major power generator. It will be one of the most efficient plants in the whole of UK. That is why it was chosen. I think this is the technology that the UK should follow. It is an exemplar project.”

| Process Parameters | Values* | Units |

| Waste Capacity | 11.1 | t/h |

| Heat Value | 9.0 | MJ/kg |

| Steam Temeprature | 440 | ᴼC |

| Steam Pressure | 65 | Bar |

| Gross Electric Output | 7.0 | MW |