Solution provider

Case

District energy

District heating

Add the case to your visit request and let us know that you are interested in visiting Denmark

Data-Driven Operations and Renovation.

Until recently, Aars Fjernvarme primarily used data for invoicing, but it seemed obvious to use the data collected on supply and return temperatures and flow to be able to look more closely at the condition of the distribution system – all the way to the end-users.

Combining two types of data sources makes it possible to generate new insight into the distribution system. The district heating company provides GIS data about the distribution system and meter data, e.g. from Kamstrup or Diehl, to Heat Intelligence, which then translates the data into a digital twin of the distribution system named Heat Intelligence. The model can be accessed online and used directly to optimise operation of the distribution system.

The idea came from Kamstrup, based on conversations with customers. A need to use the meter data for other and more purposes than invoicing consumers was identified. The company needed an optimisation tool. In Heat Intelligence, temperature and flow data are coupled with GIS data on the distribution system. GIS data includes pipe lengths, pipe diameters, degree of insulation and age of pipes.

This is a commercial product, and Aars Fjernvarme has served as a close sparring partner in ongoing development of the system.

Aars Fjernvarme has gained completely new insight into their network. Temperatures can be monitored to and from each customer, and this data can be linked to the flow in each service pipe and compared with the length, dimensions, insulation and age of the pipes.

This is valuable knowledge when monitoring the condition of the network and planning renovations and replacements. Aars Fjernvarme can now identify problems related to excessive heat loss much more quickly and better assess which branch pipes are expendable. The district heating company can also find places where it may be necessary to establish a temporary branch pipe due to lack of demand.

As Aars Fjernvarme optimises the network, the supply temperature can be lowered even more, and this will reduce transmission losses. Aars Fjernvarme is continuously working to lower consumers’ return temperature, as this will directly reduce heat loss from the return pipes and increase their energy production at the waste incineration plant, which includes flue gas condensation. The return temperature is important for the efficiency of flue gas condensation.

This directly affects the company’s operating budget. Besides lower supply and return temperatures, Aars Fjernvarme also achieved a better understanding of the hydraulics of the distribution system. It has become much easier to ensure supplies of the temperatures customers want.

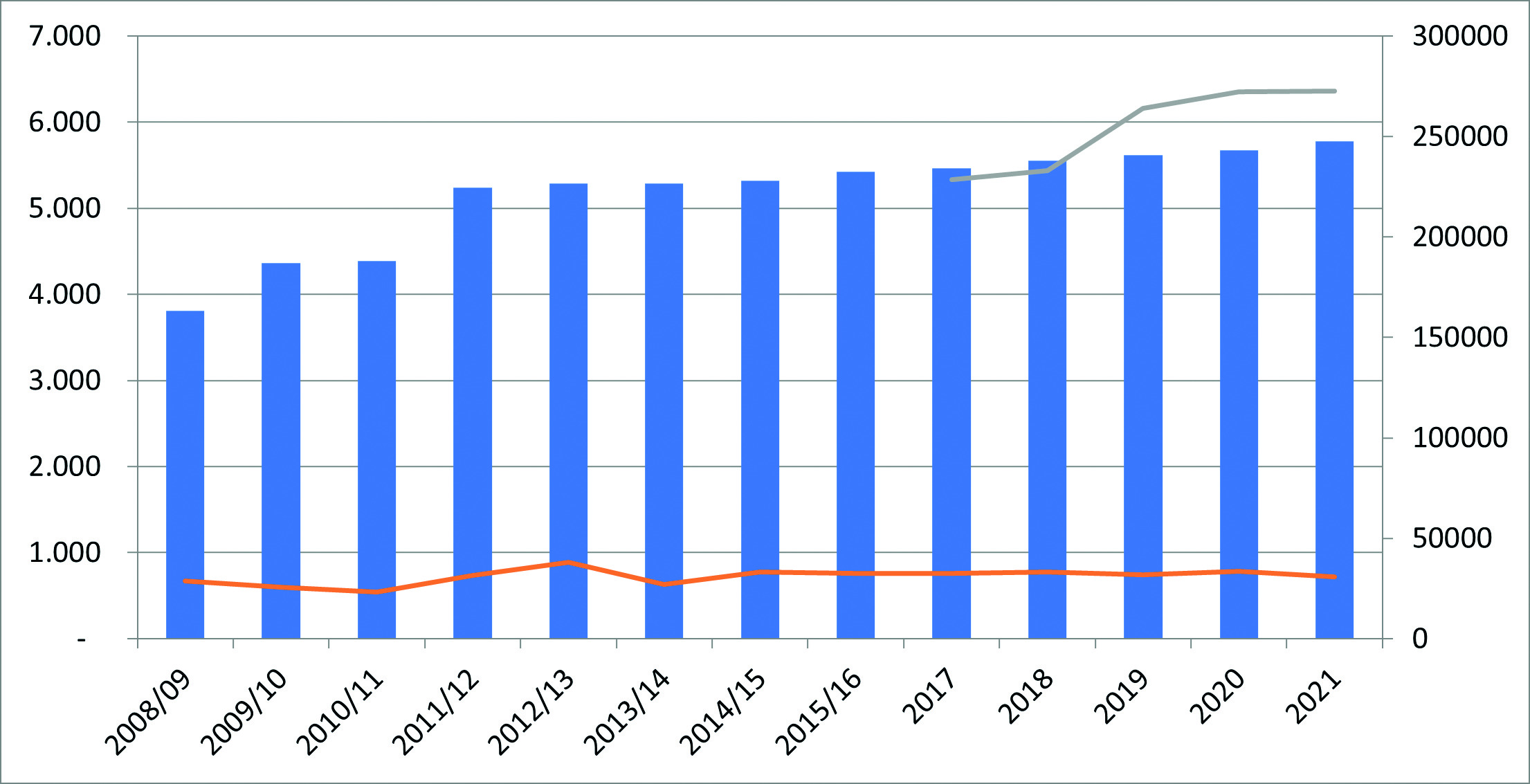

Teaching Kamstrup’s organisation how district heating companies think and work has been challenging. Aars Fjernvarme has spent a lot of time removing teething troubles rom the system and gearing the system for larger supplies. There are still challenges, but hopefully they will be resolved in the long term. The orange line in the diagram shows the number of MWh lost in the distribution system per year, and the columns show the number of consumers connected to the distribution system. The grey line shows the increasing number of metres of pipes necessary to connect more consumers. The result of Heat Intelligence is basically that Aars Fjernvarme can reduce transmission losses by approx. 1,500 MWh/year even though it continues to connect around 100 more consumers a year and is expanding the network by several kilometres every year.

The figures in the graph show 2,788 MWh, but the graph includes another project completed by Aars Fjernvarme that has reduced transmission losses by a further almost 1,300 MWh.