Solution provider

resolvent brings innovation, digitalization and sustainability into your business.

Case

Energy storage

resolvent brings innovation, digitalization and sustainability into your business.

Add the case to your visit request and let us know that you are interested in visiting Denmark

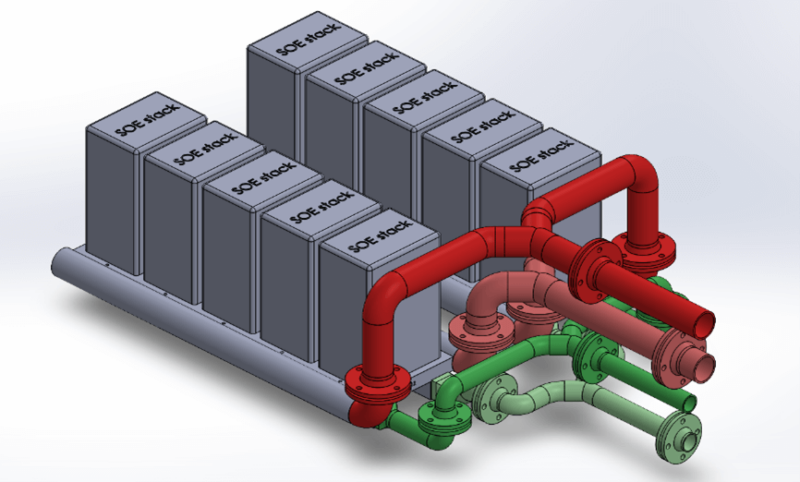

One of the challenges encountered when upscaling electrolyzer technologies from a single stack to multiple stacks is to achieve a uniform flow distribution across the stacks while maintaining a pressure drop across the system as low as possible. Ensuring that each stack receives the same amount of fuel and air is vital for efficient hydrogen production. It is thus important to carefully design and optimize the electrolyzer unit’s fuel and air distribution systems early in the design process to maximize its performance. Parameters such as size, shape, and orientation of the fuel and air flow channels are all relevant to investigate, but building and testing prototypes with different geometrical configurations would take too long and be too costly in early design stages.

To address the challenge of achieving uniform fuel and air flow distribution across the stacks of the electrolyzer unit, a CFD analysis was conducted. A few key modelling assumptions were made:

When the electrochemical reactions occurring within the stacks are not explicitly modelled, the fuel and air sides of the system are decoupled. Therefore, separate CFD analyses were done for the fuel and air sides:

The CFD analyses provided valuable insights into the flow distribution and pressure drop within the electrolyzer unit. The results from the studies conducted on the fuel and air sides are as follow:

a)

b)

Figure 4: Mass flow distribution across the stacks on the air side (a) before rescaling, and (b) after rescaling of the channels.