Case

Bioenergy

Biomass

CHP

+4

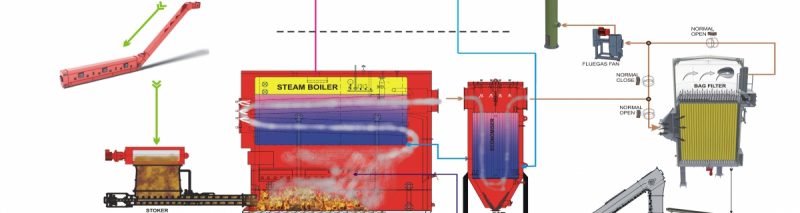

Combustion of Biomass & Steam Production

Want to see this solution first hand?

Add the case to your visit request and let us know that you are interested in visiting Denmark

Process Steam production

Weiss solutions are perfect for food producers, agricultural sector, furniture producers etc.

The most common way of utilizing biomass is direct combustion that results in hot flue gases producing steam in a boiler. Up to 70% in fuel costs can be saved by using biomass such as: straw, wood chips, waste from crops, husk,etc. Weiss designs energy plants tailor made for customers' needs and requests.

Process steam can be used in many production processes like: cooking, baking, boiling, cleaning, destillation, pasteurization and others, where high temperature is required.

You can get economical benefits by using biomass instead of gas or other fossil fuels.

This solution is very popular recently i.e. in Bulgaria ( alcohol production process):

- Reduce energy costs

- Plan against future increases in energy costs

- Environmentally friendly steam production

- Very short investment pay-back time when replacing gas or oil fuels

- Getting a green profile

- Getting a reliable plant

- Fully automated solution