News

Recycling of waste to material

Waste management

Waste prevention

Still great potential for the industry to contribute to a circular economy

A new survey among 490 union representatives of the trade union Danish Metal shows that many companies work with recycling and reuse of resources - but untapped potential remains.

Around half of the companies work with recycling and resource efficiency

In the survey, the union representatives were asked whether their company has implemented different types of circular approaches. Around half of the union representatives indicated that their company works with designing products that reduce resource consumption and extend product life. Only one fifth of the representatives indicated that their company offers service solutions or take back programs.

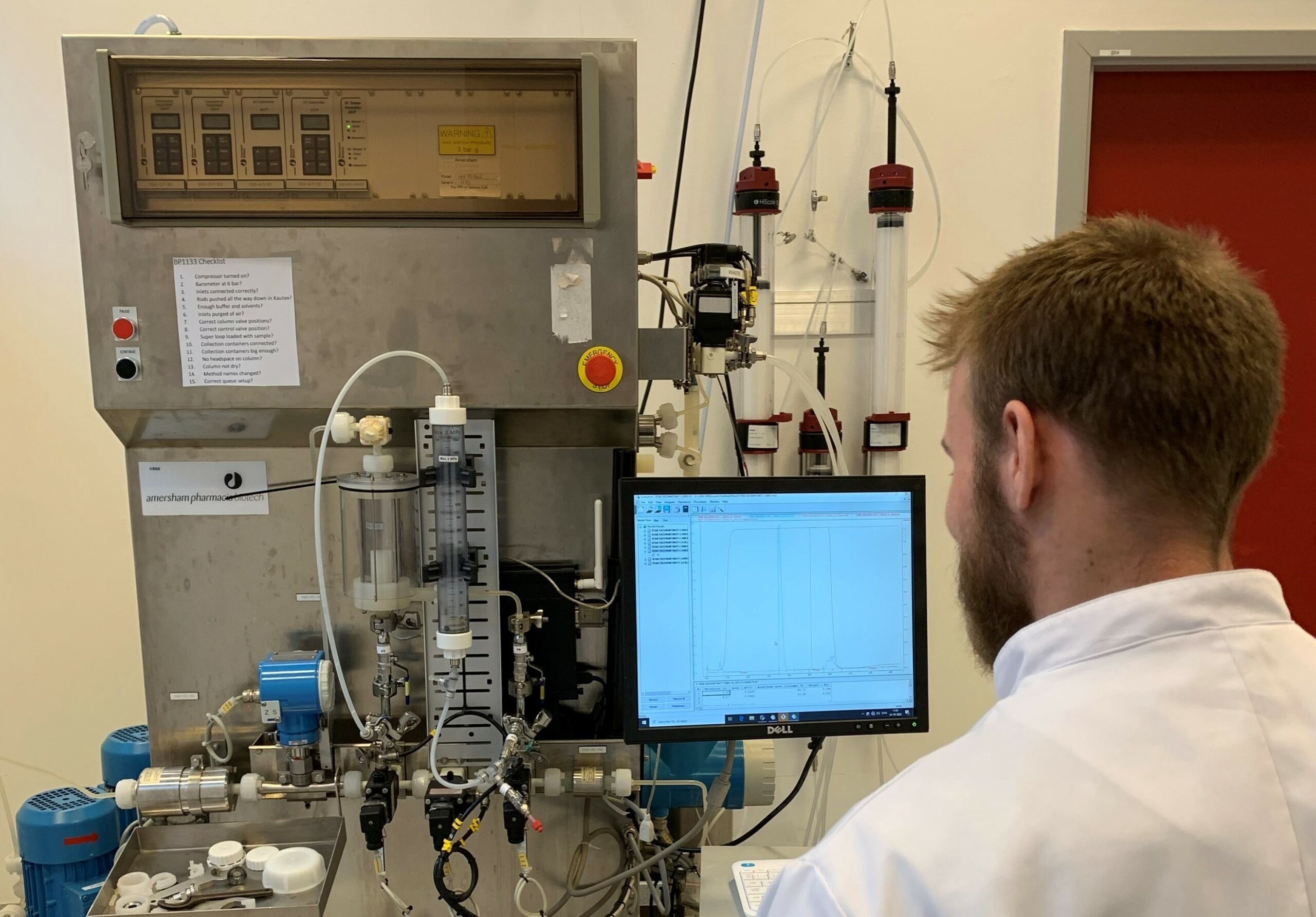

[caption id="attachment_99570" align="aligncenter" width="678"]

“It's a great that so many are working with circular economy in one form or another. That is a positive thing," says Michael Søgaard Jørgensen, Associate professor in sustainable innovation and circular transition at Department of Planning, Aalborg University. He points out that the survey does not just deal with 'simple recycling', but also includes important measures such as extending the lifespan of products through design and reparation.

-Related solution: Strategy for Circular Economy

Circular economy barriers in the industry

As Figure 1 shows, there is still large untapped potential for reducing resource consumption and developing circular business models. The survey gives several explanations as to why some companies do not work with circularity. For instance, one fourth of union representatives point out that "lack of will and interest" in the company is an important barrier to more sustainable production.

[caption id="attachment_99558" align="aligncenter" width="681"]

Knowledge sharing is key to enable the transition

Chief Economist of Danish Metal Thomas Søby believes that answers indicating “a lack of will and interest” in reality reflect a lack of knowledge - that companies simply do not realize the opportunities nor the tools available. The union believes that knowledge sharing in the field is key to address this issue and to accelerate the transition towards circularity in the industry.

Indeed, as companies remain challenged by rising resource prices, eliminating waste by reusing materials to the maximum extent allows both production cost savings and less resource dependence. Therefore adopting circular business models will not only address the environmental and socio-economic concerns, but will also create competitive advantage.

-Related solution: New Circular Economy Tool for Companies

Danish Metal conducted the electronic survey during the period of March 25 to April 15, 2019. The survey was shared among 920 union representatives and a total of 490 participated in the survey.

Sources:

Danish Metal (full report in Danish)

Photo: Kontraframe