FUBAF is a spin-off project from the lighthouse project VARGA and is supported by the Ministry of Environment of Denmark, through the Ecoinnovation/MUDP program. The partners in the project are EnviDan (project manager), BIOFOS, DTU Environment, LiqTech, Unibio, ARC, Aarhus Vand and VandCenter Syd. The experimental part of the project is taking place at Avedøre wastewater treatment plant (WWTP) in Copenhagen, Denmark, which is operated by BIOFOS and at the laboratory facilities at DTU Environment, Denmark.

The project investigates the production of Single Cell Protein (SCP) from biogas. Different carbon sources are being tested, including raw biogas as well as biologically upgraded biogas. Biologically upgraded biogas potentially has an advantage, since more methane is produced from the CO2 in the raw biogas, and thus a large amount of proteins can be produced. Biologically upgrading of biogas has been successfully demonstrated on a laboratory and pilot scale during the project. Methane content of >90 % (>95 % in some periods of operation) in the upgraded biogas has been secured.

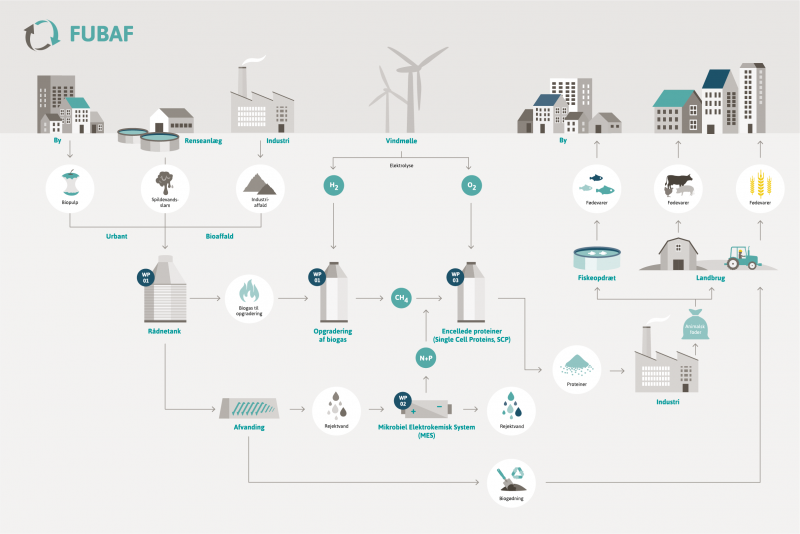

In the project, biogas from anaerobically digested municipal organic household waste is led to the pilot reactor, where the biogas is upgraded to biomethane by means of methanogenic microorganisms (archaea). The microorganisms are converting the carbon dioxide in the biogas to methane by adding hydrogen. In the next step, methane-oxidizing bacteria (MOB) produce SCP from methane, oxygen, and nutrients. The produced SCP can potentially be used in the production of feed as a substitute for conventional proteins, e.g. soybeans.

One of the key nutrients to produce SCP is nitrogen, which is extracted from the digestate through electrochemical (and even bioelectrical) extraction. The development of this process is part of the FUBAF project, and it has been demonstrated on a laboratory scale at DTU Environment.