News

Biogas

Wastewater management

Water management

Learn How Wastewater Can Be a Source of Clean Energy

Reduction of energy consumption

On a global level, it is estimated that about 2% of the world’s total energy consumption is used for collecting and treating wastewater. In Denmark, 2-3% of the country’s total energy use relates to wastewater, and there is a great potential for energy savings and energy recovery in wastewater treatment.

As a result, most wastewater treatment plants in Denmark have invested in an assessment of different ways to reduce their energy consumption. These include implementation of online monitoring and energy management systems, replacement of surface aeration by more energy efficient bottom aerators and different operational approaches.

New focus towards energy self-sufficiency

In the recent years, Danish water utilities have moved beyond simply focusing on reducing energy consumption, to also focusing on energy production. The first goal is typically to become energy neutral, and the second goal is being able to sell excess electricity and heat to the local electricity and heating companies.

- Browse through more than +1,400 solutions from +600 Danish companies

Some of the largest water utilities are already well on their way. In Denmark’s second largest city, Aarhus, the Marselisborg WWTP produced 30% more electricity than the amount consumed by the plant itself in 2015. At the same time the treatment plant produced 80% more heat than it consumed, resulting in a total net energy production of just above 150%. In Odense, Denmark’s third largest city, the Ejby Mølle WWTP achieved similar levels of total net energy production. As a next step, the water utilities in both cities are now looking into recovering the heat from the wastewater before it is discharged with the additional benefit of reducing the temperature impact on the receiving waters.

Solutions depend on plant design and context

More and more wastewater treatment plants in Denmark are upgraded with anaerobic digestion of sludge and/or codigestion with organic waste products and they utilise the produced biogas to generate electricity and heat. The optimal solutions depend on the individual plant design and the possibilities for either internal use or external sale of the produced electricity or heat. The tipping point for which the implementation of anaerobic digestion is financially viable depends on the development of new technologies and changes in the price structure for purchase and sale of electricity and heat. In Copenhagen, a new technology is currently under implementation which allows for upgrading biogas to a quality which is similar to natural gas or vehicle fuel.

- Download: White Paper "Unlocking the Potential of Wastewater"

Heading for an energy neutral water cycle By introducing new technologies to reduce energy consumption and improve energy production, it is the goal that the utility companies can provide an energy neutral water cycle. In this scenario the energy production from the utility’s treatment plants is able to cover the energy consumption related to its groundwater extraction, water treatment, water- and wastewater transport as well as wastewater treatment. In 2015, Aarhus Vand demonstrated a 90% net energy production for the water cycle in Marselisborg catchment area (Aarhus city centre).

Benchmarking and innovation lead to lower costs

The innovation of new wastewater treatment optimisation and cost-efficient solutions for both the construction and operation of infrastructure is largely driving by the fact that Danish water utilities are subjected to mandatory benchmarking on operational parameters and cost efficiency across the water sector. Innovation projects are often based on collaboration across governmental bodies, water utilities, consulting companies, technology suppliers, universities and research institutions.

Cases

Achieving 153% energy self-sufficiency at WWTP, Aarhus, Denmark

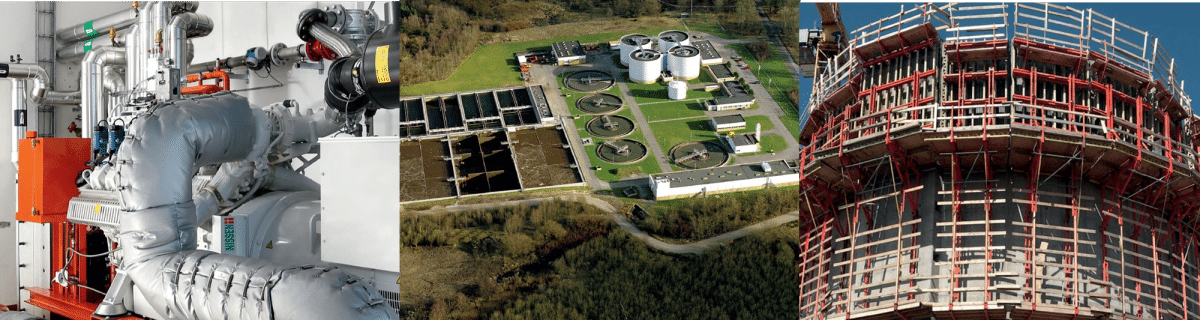

Over the past five years, the water utility Aarhus Vand has put great focus on energy savings and energy production. At its Marselisborg WWTP, the utility has implemented energy-saving technologies such as an advanced SCADA control system, a new turbo compressor, sludge liquor treatment based on the anammox process, as well as optimised the fine bubble areation system. This has resulted in a reduction in power consumption of approximately 1 GWh/year which corresponds to about 25% in total savings. During the same time period, the energy production has been improved through implementation of new energy efficient biogas engines (CHP), resulting in an increase in electricity production of approximately 1 GWh/year. Furthermore, a new heat exchanger has been installed with the aim of selling surplus heat to the district heating grid, which represents approx. 2 GWh/year. In 2015, Marselisborg WWTP had a total energy production of 9,628 MWh/ year and an energy consumption of 6,311 MWh/year, equivalent to a net energy production of 153%. Most of the installed technologies have a payback time of less than 5 years.

(Courtesy: Aarhus Vand)

Construction of two new thermophilic digesters, Copenhagen, Denmark

From 2013 to 2018, the wastewater utility BIOFOS will increase the digester capacity to a total of 30,000 m3 at Denmark’s largest municipal wastewater treatment plant Lynetten. During the project, BIOFOS will construct two new digesters with a capacity of 6,000 m3 each. The aim of the project is to ensure a more flexible and optimised operation. Future scenario projections show that Lynetten will receive higher amounts of sludge and therefore requires more capacity to meet this increased demand. By increasing the capacity, Lynetten will be able to produce more biogas to be injected into the Copenhagen city-gas network and thereby reduce CO2 emissions produced by traditional methods of gas production. BIOFOS is collaborating with the two Danish consulting companies, Rambøll and EnviDan, on design, preparation of tender packages and supervision during the construction phase. During the design phase, the project group has worked towards a project which focuses on key aspects such as operational cost, high quality, low maintenance and health and safety during both the construction phase and in the daily operation.

Maximising the value of wastewater, Odense, Denmark

In many countries, water and wastewater services are seen as public goods paid for by the state. However, in Denmark and in other member states of the European Union the ‘polluters-pay-principle’ applies to both domestic and industrial users, which means that the cost of wastewater collection and treatment must be covered by the water tariffs. Wastewater collection and treatment costs are typically twice the size of the water abstraction and supply costs, which means that cost-efficient solutions are imperative to ensure affordable wastewater treatment for water users and polluters. In the City of Odense in Denmark, the largest wastewater treatment plant — with a capacity of 385,000 person equivalents (PE) — has achieved a degree of electricity self-sufficiency of more than 110% through optimisation of the plant’s existing infrastructure. Further optimisation opportunities have been identified in cooperation with a number of consulting companies, which will enhance nutrient reuse and maximise biogas extraction for additional heat and electricity production.

(Courtesy: VCS Denmark)

Becoming energy self-sufficient, Esbjerg, Denmark

In Esbjerg, the fifth largest city in Denmark and an important port city, one of the city’s wastewater treatment plants was in recent years optimised and expanded to a hydraulic capacity of 64,000 m3/hour and sludge-related capacities for 160,000 person equivalents (PE) resulting in substantial increase in energy consumption. However, by additional investment in sludge digestion tanks and by utilising the produced biogas to generate electricity the plant is now self-sufficient in energy.

(Courtesy: NIRAS)

You should consider reading

solutions

Climate change adaptation

+4

WATER CONSERVATION IN AFRICA

4 November 2024Perspective

Sector coupling

+9