Old technology given new life

There is nothing new about producing hydrogen from wind power — in Denmark, at least. Back in 1894, the inventor Poul la Cour used electricity from a wind turbine to split water into oxygen and hydrogen gas. The gases were separately collected in tanks, stored in bottles, and used to light buildings, such as the Askov Folk High School.

How green hydrogen can be utilised

While producing green hydrogen through electrolysis is not a new technology, the hydrogen currently used in industrial processes is predominantly fossil-based, being derived from gas and coal. Today’s hydrogen supply accounts for 1.7 percent of the global annual energy consumption and emits 830 million tonnes of CO₂ annually. Only about 1 percent is based on renewable energy. As global renewable energy continues to grow rapidly, the potential for substituting fossil-based hydrogen with green hydrogen represents vast opportunities for emissions reductions.

Green hydrogen can be utilised in many parts of the energy system, either in its pure form or as a building block in further refining processes. As a fuel, green hydrogen is

completely free of harmful emissions; a vehicle fuelled by hydrogen, for example, only emits water vapour.

The importance of water

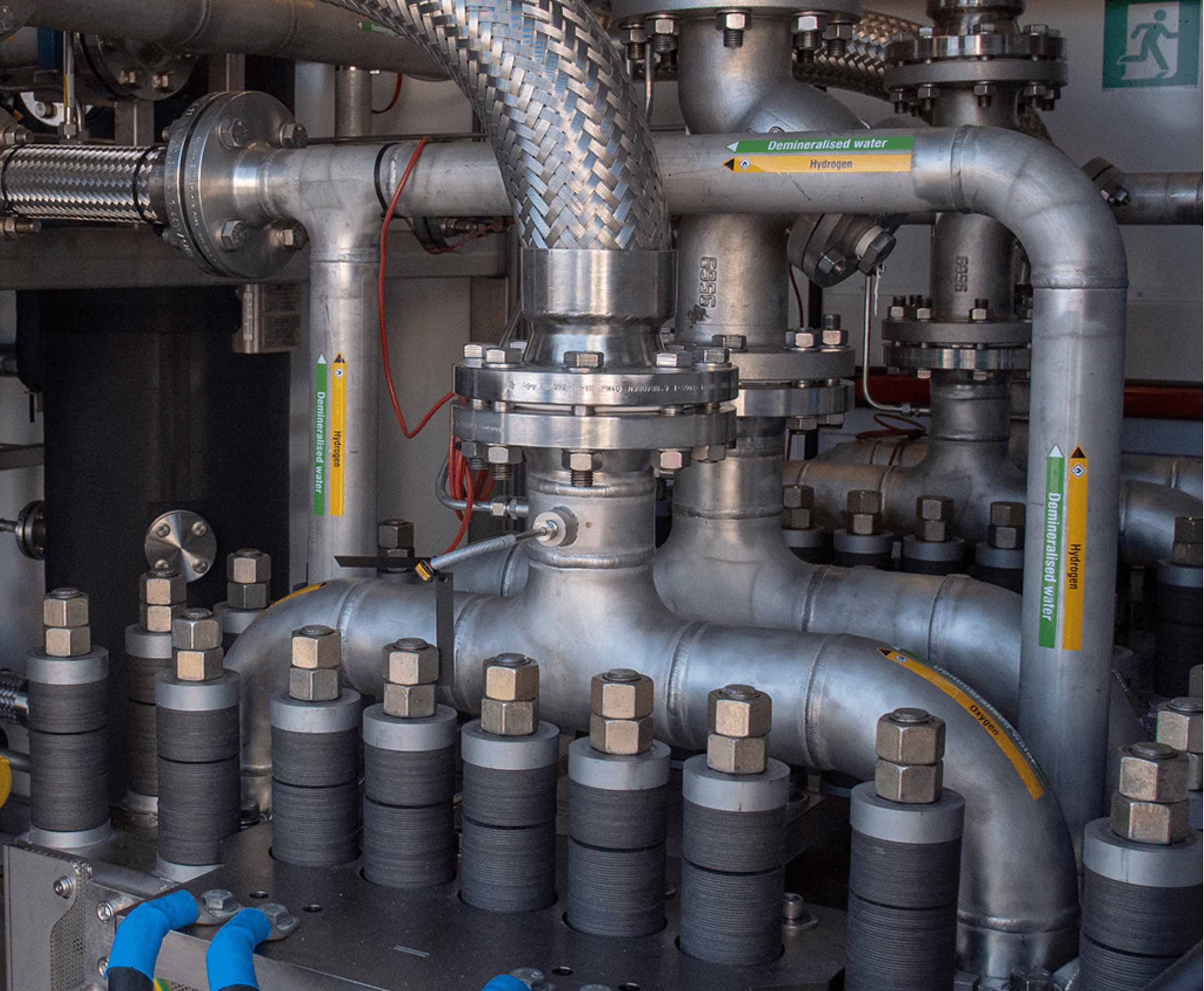

Water is the basis of electrolysis and presents its own challenges and opportunities. The purity of the water is essential, and this raises questions on how to supply the necessary quantities of sufficiently pure water. As drinking water is a very scarce global resource, Danish efforts to develop suitable solutions for electrolysis focus on purifying wastewater and using groundwater from areas where the water level is problematically high and cannot be used for consumption. In this way, electrolyser plants can contribute to a new water ecosystem which uses low-quality water from other sectors, including wastewater from private households. While technologies within wastewater treatment and water purification already exist in Denmark, the Danish water industry is also working on new technologies to solve these challenges.